Are there special request qty for the trial order?

- Share

- Issue Time

- May 5,2017

In the fast - paced world of modern technology, the demand for efficient heat dissipation is skyrocketing. To better understand why our heat sinks stand out from the crowd, let's first delve into what a heat sink is and its wide - ranging applications.

A heat sink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature at optimal levels. This fundamental principle underlies the crucial role heat sinks play in various industries.

In computers, heat sinks are used to cool central processing units or graphics processors. These components generate a significant amount of heat during operation, and without proper cooling, their performance can degrade rapidly, leading to system slowdowns or even crashes. Our custom 4 - copper - heat - pipe CPU fans are specifically designed to address this need. By efficiently transferring heat from the CPU to the fins and then to the surrounding air, they ensure that the CPU remains at an optimal temperature, even during high - load gaming or complex graphics processing.

Heat sinks are also used with high - power semiconductor devices such as power transistors and optoelectronics such as lasers and light - emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature. In these applications, the reliability and performance of the devices heavily depend on effective heat dissipation.

Dear buyer,

Many thanks for your selecting Ruiquan Hardware.

About the trial order qty, we have no special request, you can select 100PCS, 200PCS, 300PCS.

According to your real situation, you can send your order to us, we will try our best to offer service for you.

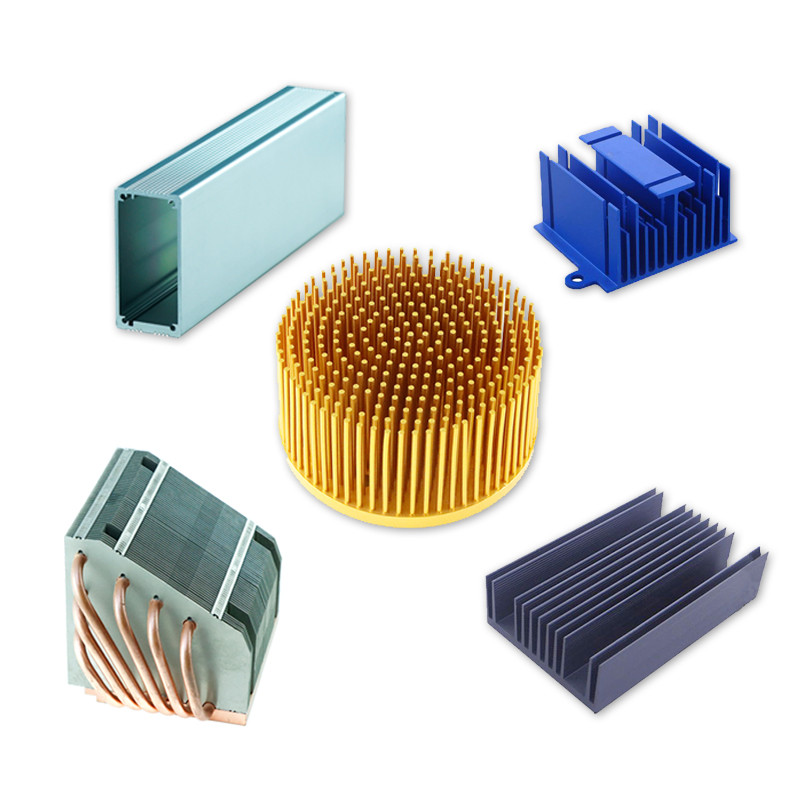

We offer a diverse range of heat sinks, including aluminum extrusion heat sinks, which are known for their efficient heat dissipation through their carefully extruded fin structures. Our cold forging heat sinks, on the other hand, provide enhanced durability and precision in their construction. Additionally, we have aluminum housings that not only offer protection but also contribute to heat dissipation. And our CNC products, crafted with high - precision machining, ensure top - notch quality.

Welcome to visit our factory in your free time. Our state - of - the - art facilities, which we moved into in 2023, are equipped with advanced manufacturing equipment and a dedicated team of professionals. A visit to our factory will give you a firsthand look at our production processes, from the raw material selection to the final quality inspection. You can witness how we transform materials into high - performance heat sinks that meet the most stringent industry standards.

Our heat sinks demonstrate unrivaled cooling performance, thanks to years of deep - rooted efforts in the heat dissipation field and continuous technological upgrades. Every step, from the addition of 3500 - ton and 1000 - ton cold - forging heat - sink equipment in 2017 to the relocation to a new factory in 2023, has laid the foundation for enhancing cooling performance.

In terms of material selection, we meticulously choose copper and aluminum with high thermal conductivity. Take copper heat pipes as an example. Their extremely high thermal conductivity allows for the rapid extraction of heat from heat - generating sources. In our custom 4 - copper - heat - pipe CPU fans, through a carefully designed heat - pipe layout, heat is ensured to be transferred evenly and efficiently to the cooling fins. These fins, manufactured through precision cold - forging processes, have a larger surface area, enabling sufficient contact with air to accelerate heat dissipation.

Advanced manufacturing processes also guarantee superior cooling performance. The high - precision equipment in the new factory enables us to achieve more accurate dimensional control during production. For instance, the processing accuracy of cold - forging heat sinks can be precise to the millimeter level, ensuring a tight fit between various components, reducing thermal resistance, and further enhancing heat dissipation efficiency.

In practical applications, our heat sinks perform remarkably. Taking computer CPU cooling as an example, users who have used our custom 4 - copper - heat - pipe CPU fans have reported that during high - load gaming or complex graphics processing, the CPU temperature can be stably maintained within an ideal range, effectively preventing performance degradation or system crashes caused by overheating. For the heat dissipation requirements of industrial equipment, our large - scale cold - forging heat sinks also perform outstandingly, ensuring the stable operation of equipment during long - term continuous work and significantly reducing the probability of equipment failures due to heat - related issues.

Whether in the field of electronic devices that pursue extreme performance or in industrial production with extremely high stability requirements, our heat sinks, with their superior cooling performance, provide reliable heat dissipation guarantees for various types of equipment and have become the well - deserved ultimate cooling solution.